- Home

-

Products

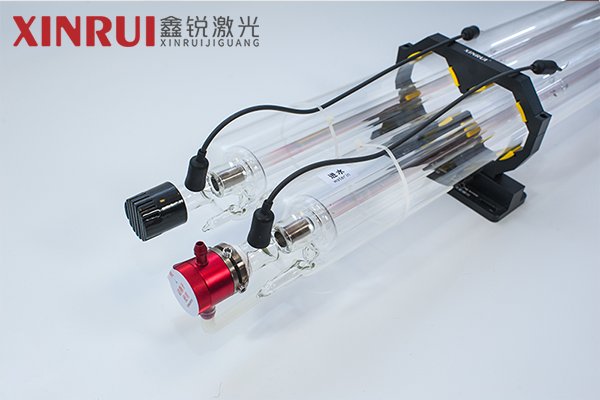

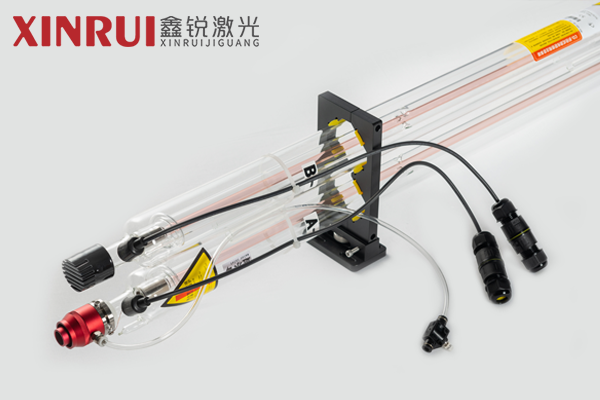

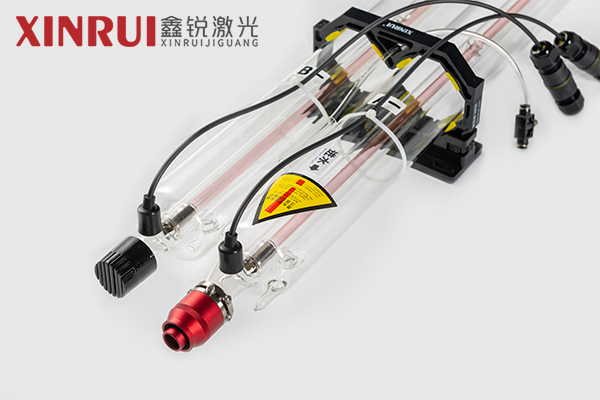

E Series CO2 laser tube

E series CO2 laser tube is a long-life enhanced CO2 laser tube developed by our company for many years. The laser tube has the advantages of high power, fine beam and stable luminescence. The discharge tube is plated with a catalyst to greatly increase its working life. Compared with similar products Small size, spot pattern is good, fast cutting speed advantage.EQ Series Sealed-off CO2 Glass Laser Tube

EQ Series CO2 glass laser tubes have the characteristics of good beam quality, sufficient power, good stability and long service life. -

Service Support

After-sales service

On the sale of any laser will be implemented perfect after-sale service and lifetime paid maintenance, which is our guarantee for you, but your worries

-

Abuout Us

Company profile

Numerous times of hard work and innovation, reform and development, laid the Xin Rui pragmatic forge ahead, rigorous and pragmatic purpose of serving

Contact us

Combined with the advanced technology and rich experience in today's international optical market, we provide the best and most comprehensive laser solutions

-

News

Latest News

Please pay attention to Xin Rui latest developments, keep abreast of the latest products

Company News

Please pay attention to Xinrui company news, keep abreast of the latest developments

Industry Info

Please pay attention to Xin Rui industry information, keep abreast of the latest industry information

Media Focus

Please pay attention to Xin Rui media focus, keep abreast of the latest media focus

-

Recruitment

Salary and welfare

We provide our employees with competitive remuneration packages in the industry

- Contact Us